Manufacture & Testing

Manufacture & Testing

Being an ISO9001 certified company, we understand that the quality of our products can never be compromised. We continue our improvement of in-house production on all aspects of production processes for higher quality and better lead times.

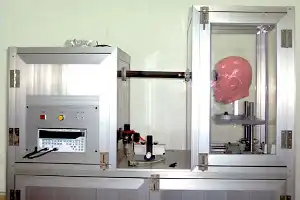

Our safety products are in compliance with relevant industrial standards, i.e. ANSI Z87.1, CE EN166, CSA Z94.3, AS/NZS1337.1, ISO ISO16321-1. We have the complete lab setup at our production location performing the needed compliance testing on safety glasses, safety goggles, faceshields, and earmuffs, plus stringent quality assurance procedures during production and for every shipment.

We not only test the products according to the global qualification standards for safety and sports products, but also perform even more stringent internal test criteria cumulated over the past decades.

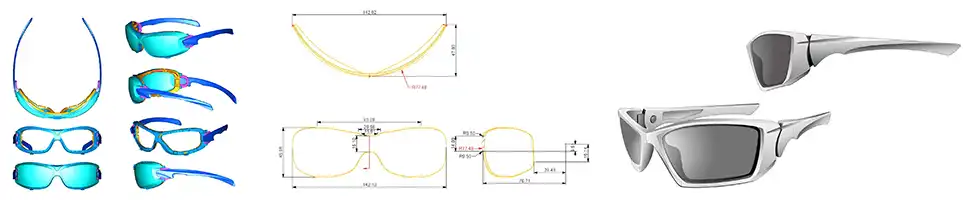

We perform the following tests that ensure safety glasses’ quality and compliance:

Our safety products are in compliance with relevant industrial standards, i.e. ANSI Z87.1, CE EN166, CSA Z94.3, AS/NZS1337.1, ISO ISO16321-1. We have the complete lab setup at our production location performing the needed compliance testing on safety glasses, safety goggles, faceshields, and earmuffs, plus stringent quality assurance procedures during production and for every shipment.

We not only test the products according to the global qualification standards for safety and sports products, but also perform even more stringent internal test criteria cumulated over the past decades.

We perform the following tests that ensure safety glasses’ quality and compliance:

- Optical Quality

- Luminous Transmission

- Heat / Cold Environment test

- Optical Power

- Drop Ball Impact Resistance

- Minimum Lens Thickness

- High Velocity Impact

- Eye Coverage and Field of View

- Penetration Test